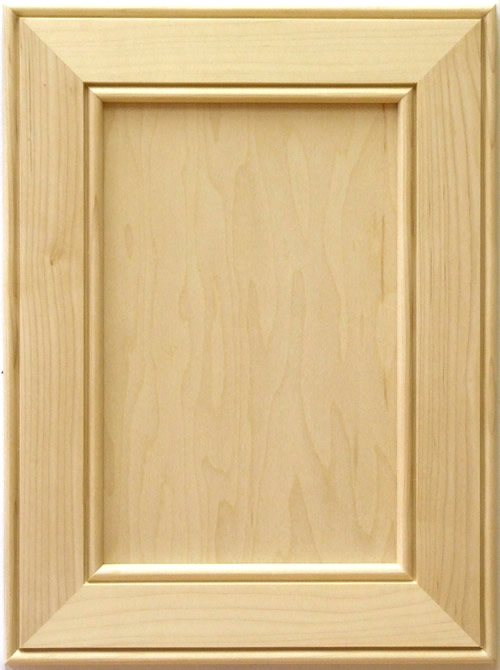

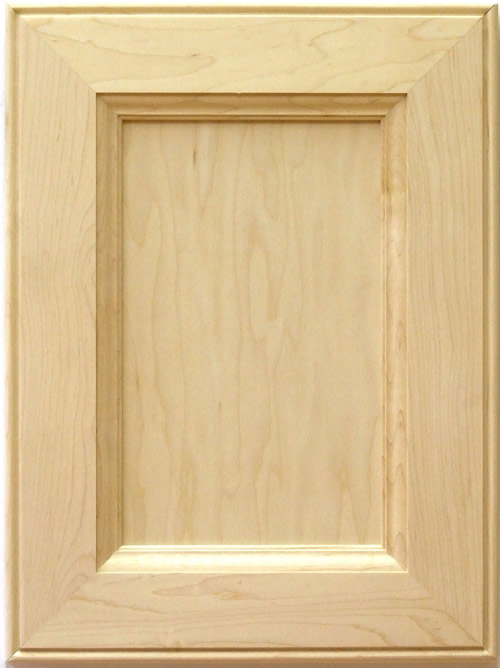

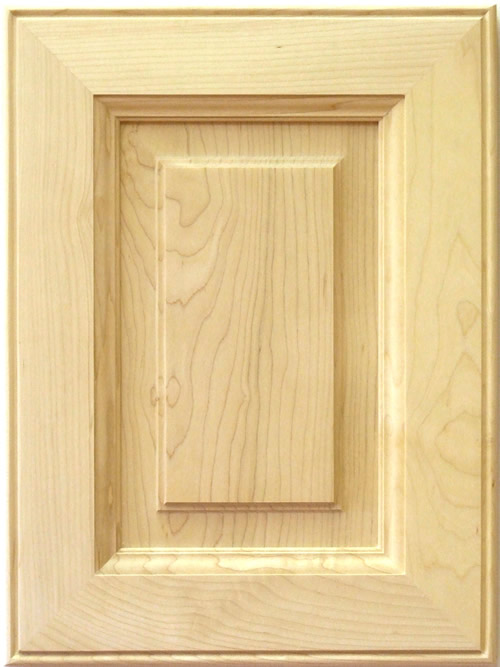

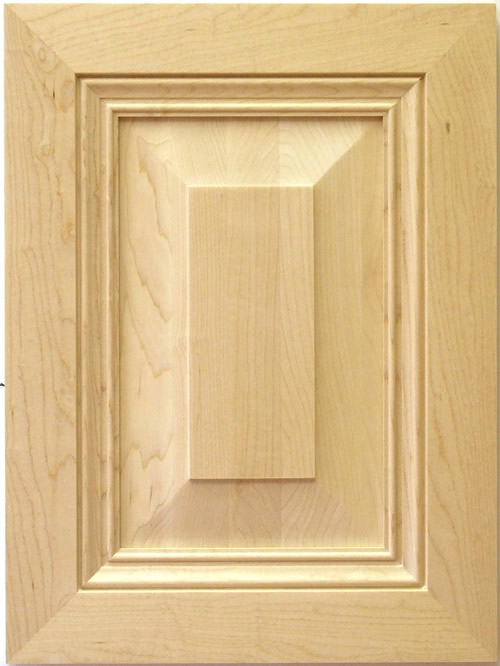

Mitered Kitchen Cabinet Doors

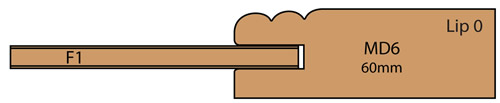

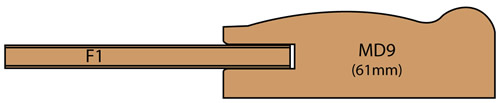

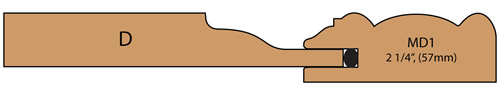

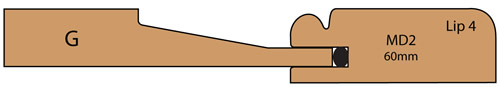

Miter doors are made from moulded rails allowing the corners to come together at 45 degrees. The mitered door is typically fancier and considered more upscale than "Stile and Rail" doors.

Allstyle uses a state-of-the-art mitering machine that simultaneously cuts both adjoining components to ensure a true 45 degree joint and a perfect fit. The machine creates a finger joint in both components as well as a dowel hole for added strength. The doors are then squared and clamped in a pneumatic frame clamp under several tons of pressure. The result is a fantastically strong joint that will remain tight for many years.

Because of the intricate details on the face of a mitered door they are completely hand sanded. This takes extra time and expense but the results are worth it.

If you would like a sample please request using our online request form.

Miter Door Assembly Clamp

Clamping up the five components of a mitered drawer front into a completed assembly. The pressure on the pneumatic pressure arms are manually adjusted by a skilled operator to ensure the frame corners come together at perfect forty-five degree angles. Notice the minor glue squeeze out as the assembly comes under final pressure. The surface glue is removed. Minor glue squeeze ensures the joint is not starved and is bonded properly.